Whether coffee with milk or tea with sugar: we are faced with the mixing of substances on an everyday basis. It is always a matter of mixing two or more substances with each other through the use of motion. The goal is always to achieve a mixture that is as homogeneous as possible. This is easy to achieve with coffee and milk. With a salad dressing made from vinegar and oil, on the other hand, the two ingredients are immiscible, so it takes only a short time for the mixture to separate. What is certainly tolerable with a salad dressing can have a lasting effect on the efficacy of a drug.

A lot therefore depends on the mixing quality and speed when it comes to process engineering. Numerous processes have therefore been established in process engineering to achieve sufficient mixing quality in the shortest possible time. Depending on the application, scaling up the process from low to higher throughputs in particular represents a major challenge.

One example is the production of nanoparticles, such as those used in mRNA vaccines. For these drugs, the active ingredient is encapsulated in a kind of protective shell so that the active ingredient is released at the right place. For this purpose, the active ingredient is dissolved in a liquid (buffer solution) and mixed with another solution (e.g. lipid or polymer solutions). Once these two liquids are mixed, nanoparticles are formed that encapsulate the active ingredient. The faster and more homogeneous this mixture is, the higher the quality of the particles.

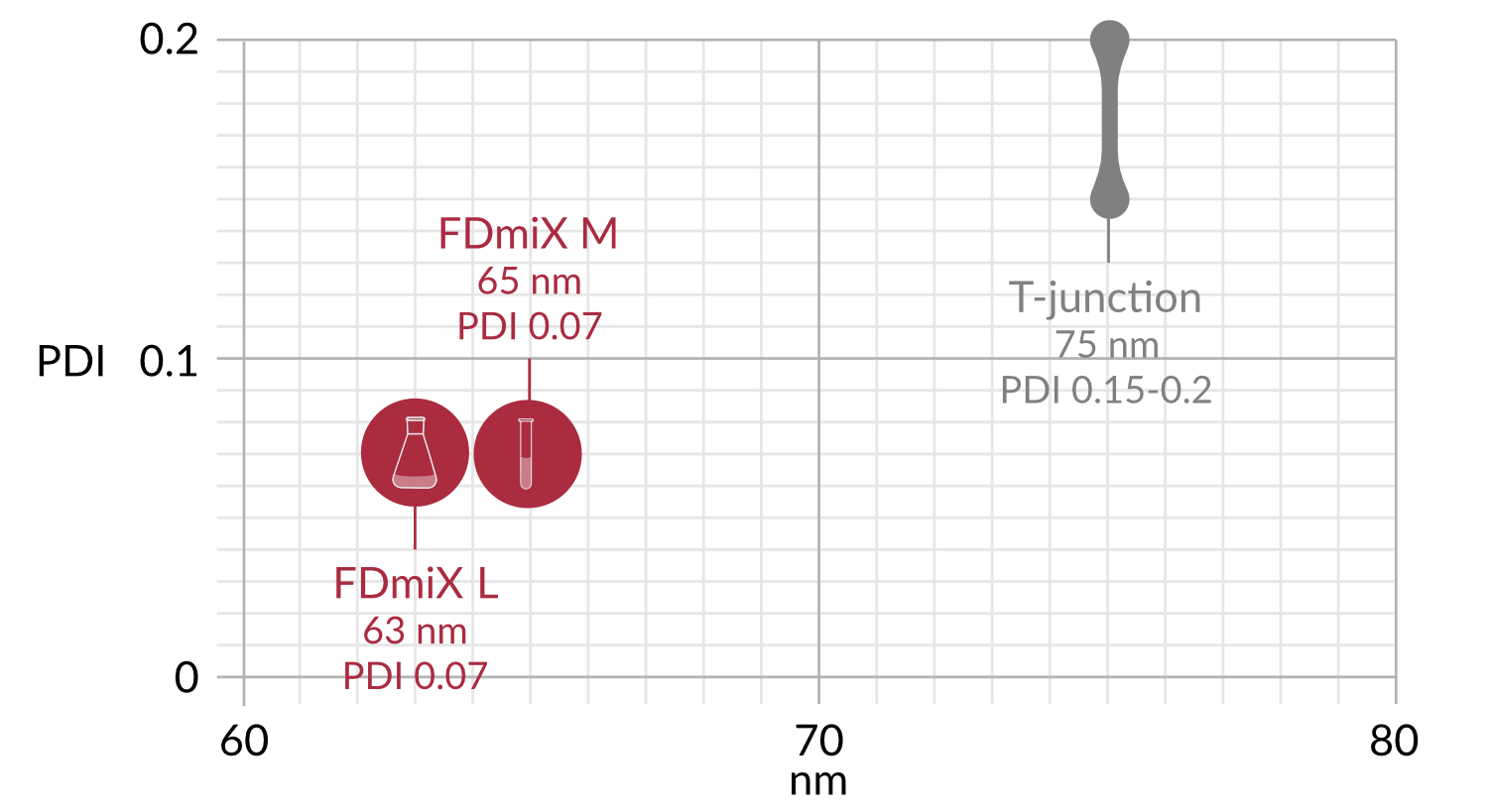

For laboratory use, so-called microfluidics can be used, which produce very good and fast mixing, but only allow a very low throughput. For industrial scale, on the other hand, there are so-called impinging mixers (also called T-mixers or Y-mixers), which allow a high throughput, but at the cost and expense of the mixing quality. This shows the fundamental problem with the upscaling of laboratory processes to series production. The situation is very similar with so-called nanoemulsions, in which a stable emulsion of otherwise immiscible substances such as water and oil is produced.

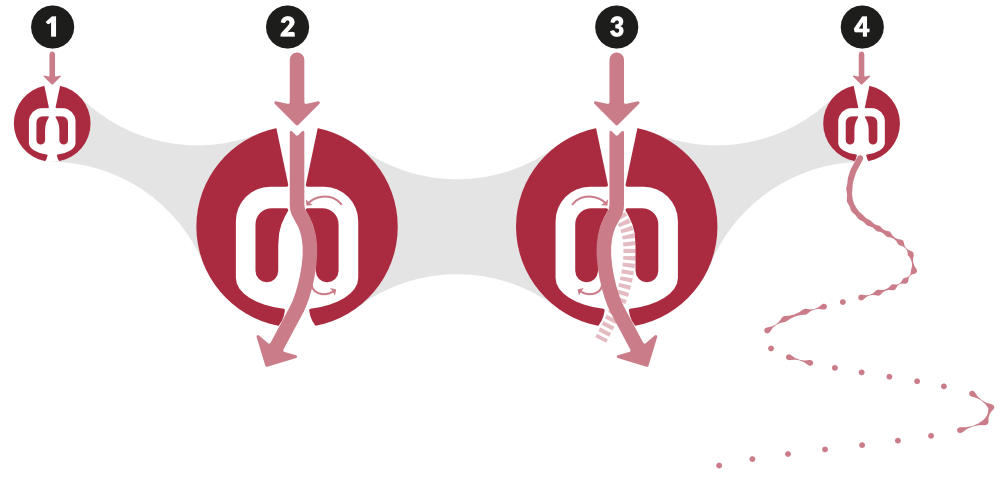

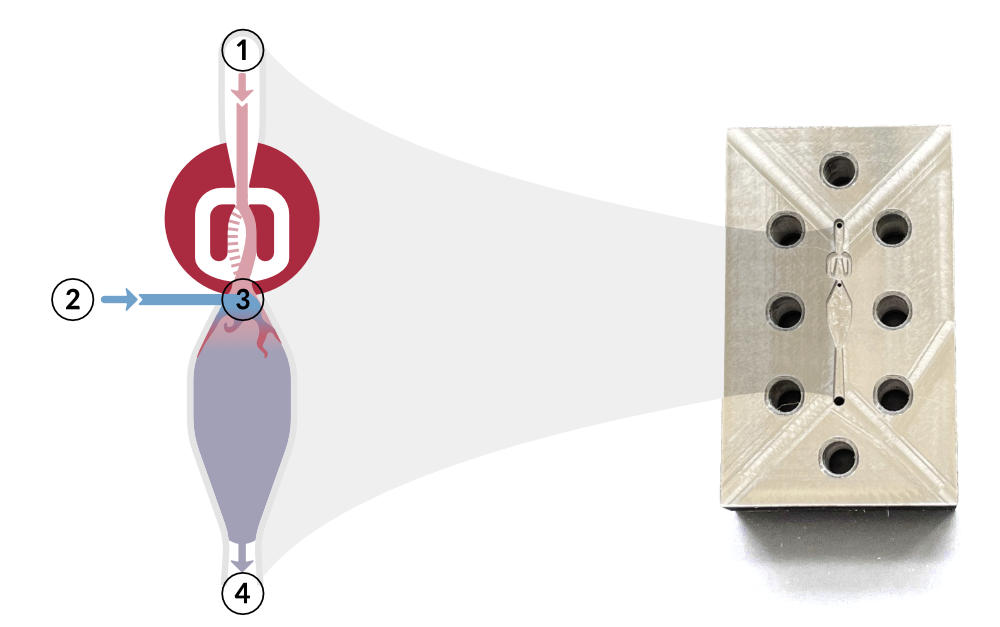

We were able to bridge the gap between mixing quality and throughput together with the Institute for Production Technology of the Fraunhofer Society based on our OsciJet technology. The resulting FDmiX platform allows consistent mixing quality and speed from laboratory use to series production and has already been successfully tested for the production of lipid and polymer nanoparticles, as well as nanoemulsion. It has been shown that the mixing quality is superior to many conventional systems. The mixers are available in different size classes and are all characterized by high robustness, very short mixing times, minimal risk of clogging and wide process windows. This makes them suitable for a wide range of applications.