Process-related, the industrial production of components (mostly) results in an undesired impact of particles (such as metal chips) and dirt films (such as cooling lubricants) on the components. To ensure the quality of subsequent processes (color coating, hardening, galvanizing, etc.) or the purity of the end product, these impurities must be removed. Since the impurities depend on the production process and the product, a variety of methods are used for cleaning. In the field of spray cleaning, special nozzles and often even elaborated mechanics are used to provide additional movement.

What do you do when you pick up a garden hose to clean something? You probably swing it forth and back when facing persistent dirty, right?

Most people do this movement intuitively, since a moving jet cleans much better due to the interrupted drop impact. So the dynamics make a big difference when cleaning.

In parts cleaning, this is no different. The movement improves the cleaning performance. In the ultrasonic bath it is the vibration, in basket or drum washing it is the (relative) movement between cleaning nozzles and the parts to be cleaned. Often even complex mechanical solutions are used to generate additional movement.

The OsciJet nozzle, on the other hand, generates a compact moving jet without complex and therefore maintenance-prone mechanics. In addition, the nozzle adopts a flow instability in its interior and thus manages without moving parts. This makes the nozzle extremely robust and practically maintenance-free. You can find out more about how it works here (Link).

The OsciJet nozzle provides improved cleaning quality through:

Compared to conventional nozzles, the OsciJet nozzle achieves:

With this we make it possible for you:

The use of OsciJet nozzles leads to:

With the innovative OsciJet nozzle you can reduce:

The OsciJet nozzle thus makes a major contribution to current and future challenges in industrial parts cleaning.

As an innovative company FDX offers you the right nozzle for your machine. From a wide range of standard nozzles we can select the right nozzle for you. For special applications, we use the latest simulation software to tailor the right OsciJet nozzle for your application.

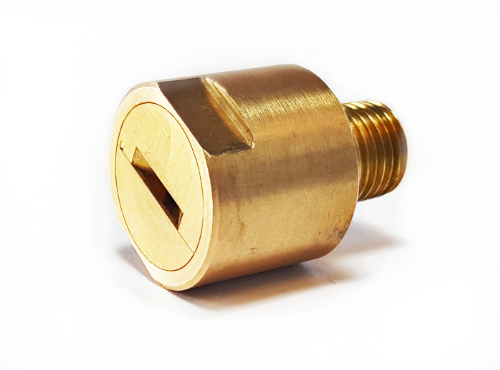

The OsciJet LPX-PC (PC stands for Parts Cleaning) is tailor made for industrial parts cleaning. The LPX-PC is available in the following versions:

To illustrate the cleaning effect, the following video shows the better cleaning performance compared to a conventional flat spray nozzle. The test soiling consists of skin cream and metal shavings mixed with cooking oil. Both contaminations have different cleaning challenges and thus show the wide range of applications of the OsciJet nozzle. Even at low pressures the efficiency of the nozzle becomes visible, which brings a greater cleaning impulse to the surface by means of a compact jet.

.