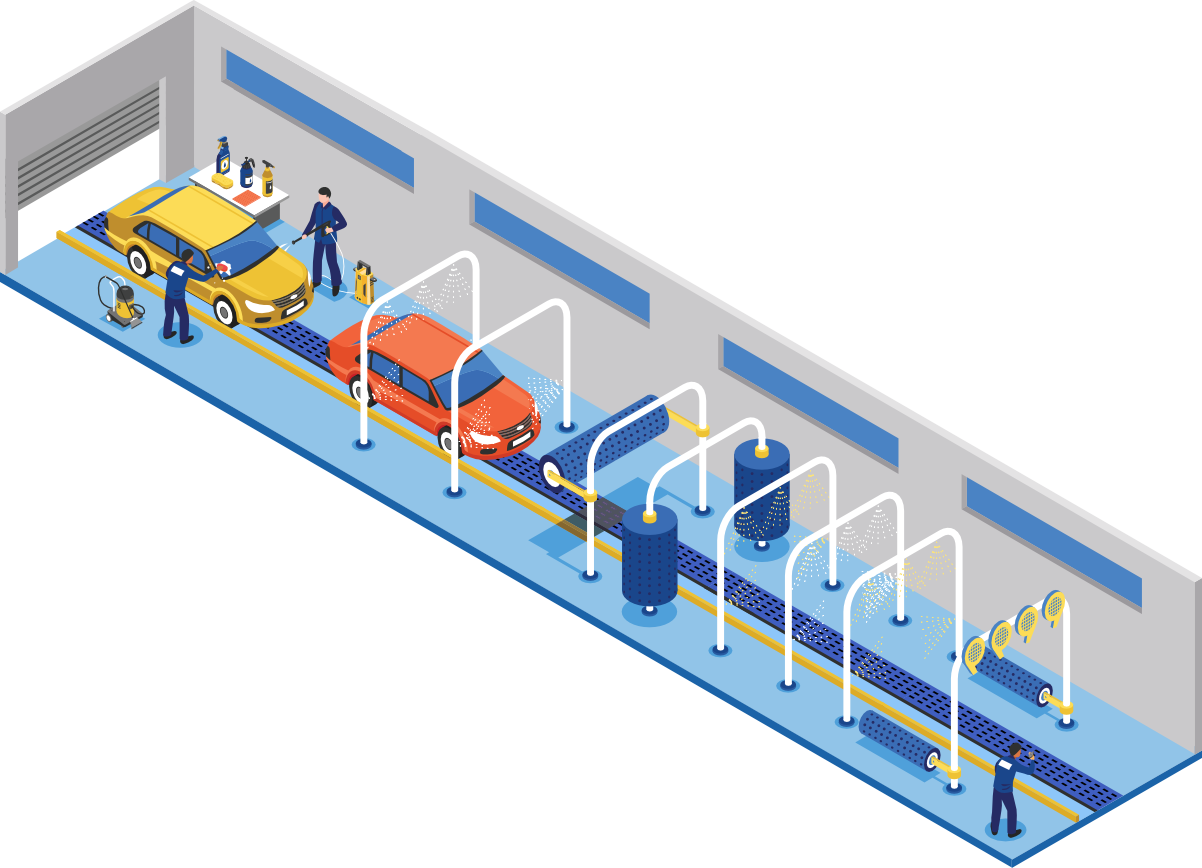

Whether portal or continuous systems, they all have in common that the protection of the vehicle and the paint is paramount. Damage to the vehicle can not only result in recourse payments, but can also quickly paralyze a system. For this reason, most systems first rinse off the coarsest dirt with a prewash and apply a liquid film that prevents dirt particles from acting like sandpaper. Of course, the wheels are particularly stubbornly dirty. Tar, road surface and brake dust form a resistant patina that is usually loosened in a separate step with high pressure and sometimes mechanically. The prewash is then followed by a foam treatment that loosens deeper-lying dirt, which is then removed mechanically with brushes and rags. Since some of the dirt is electrostatic, nothing works here without mechanical assistance. The main wash is followed by a polish treatment that removes very deep-seated dirt from the paint.

After that, everything is rinsed off again in the rinse cycle and, last but not least, a coat of wax is applied to make the paint resistant to new dirt and, in addition, a drying aid is applied to ensure that the paint dries quickly and without stains. In the end, the remaining droplets are blown off and the vehicle is clean again. In addition to the numerous cleaning agents that are matched to each process step, specially adapted nozzles are also used.

After all, to operate a carwash profitably, a high throughput is necessary, and time is a crucial factor here. But choosing the wrong nozzles quickly leads to maintenance work when they become worn or clogged. The conditions placed on the competent people in a plant are tough. In particular, the humid environment, the dirt and the cleaning agents place high demands on robustness.In the following graphic, we show you how a carwash can be optimized by using OsciJet nozzles. For the example we have chosen a continuous flow system, but the nozzles can be used just as well in a gantry system or a self-service wash box. Finally, it remains to be said that cleaning a vehicle involves more than just an aesthetic aspect. A clean vehicle contributes to driving safety, because a clean and shiny paint is more noticeable and clean windows and lights are probably self-explanatory. In addition, paint and underbody care contributes to the value retention and sustainability of a vehicle.

more …