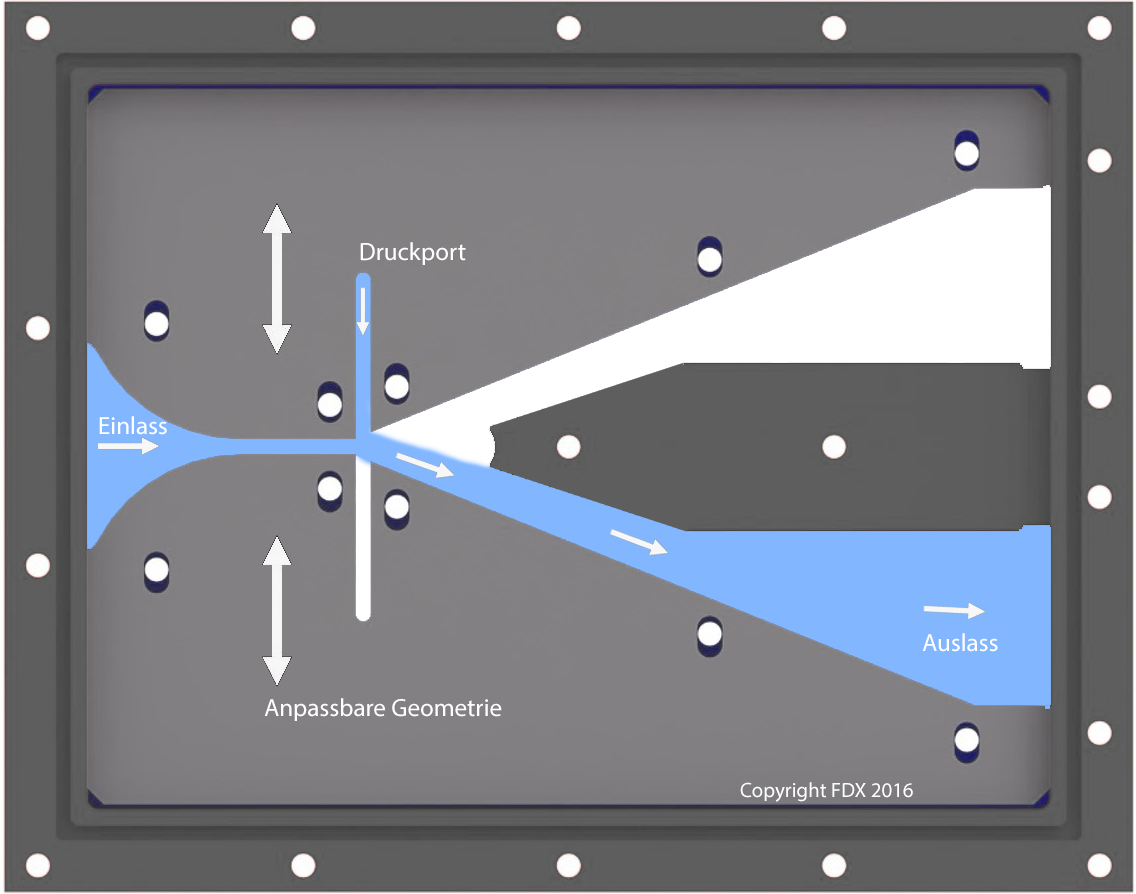

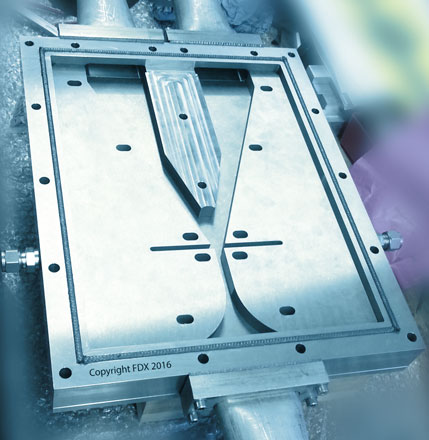

Although there were already preliminary works from the beginning of the 19th century, the first fluidic switches were not invented until the 1950s (references at the end of the page). These were intended to serve as amplifiers in (fluidic) logical circuits. The idea behind it is to redirect larger fluid mass flows (e.g. water or air) with a small mass flow. We have taken up this concept and refined it further. Our switches are very similar to fluidic oscillators (like the OsciJet nozzle), only that they can be actively switched by a valve. In the adjacent figure such a switch is shown. For active switching, a small pressure signal is applied to one of the pressure ports, which pushes the fluid jet (gases or liquids) to the opposite side. This condition remains stable even without a further pressure signal. A change of the state is however at any time possible by activating the opposite pressure port. The switches offer a few unbeatable advantages. First of all, they are extremely robust, because the absence of any mechanics means that they can not fail. So the switches can be operated even in very harsh environments with for example corrosive or very hot media. Secondly, fast switching valves can be used and so even very large mass flows can be switched very fast, because the switches switch very fast.