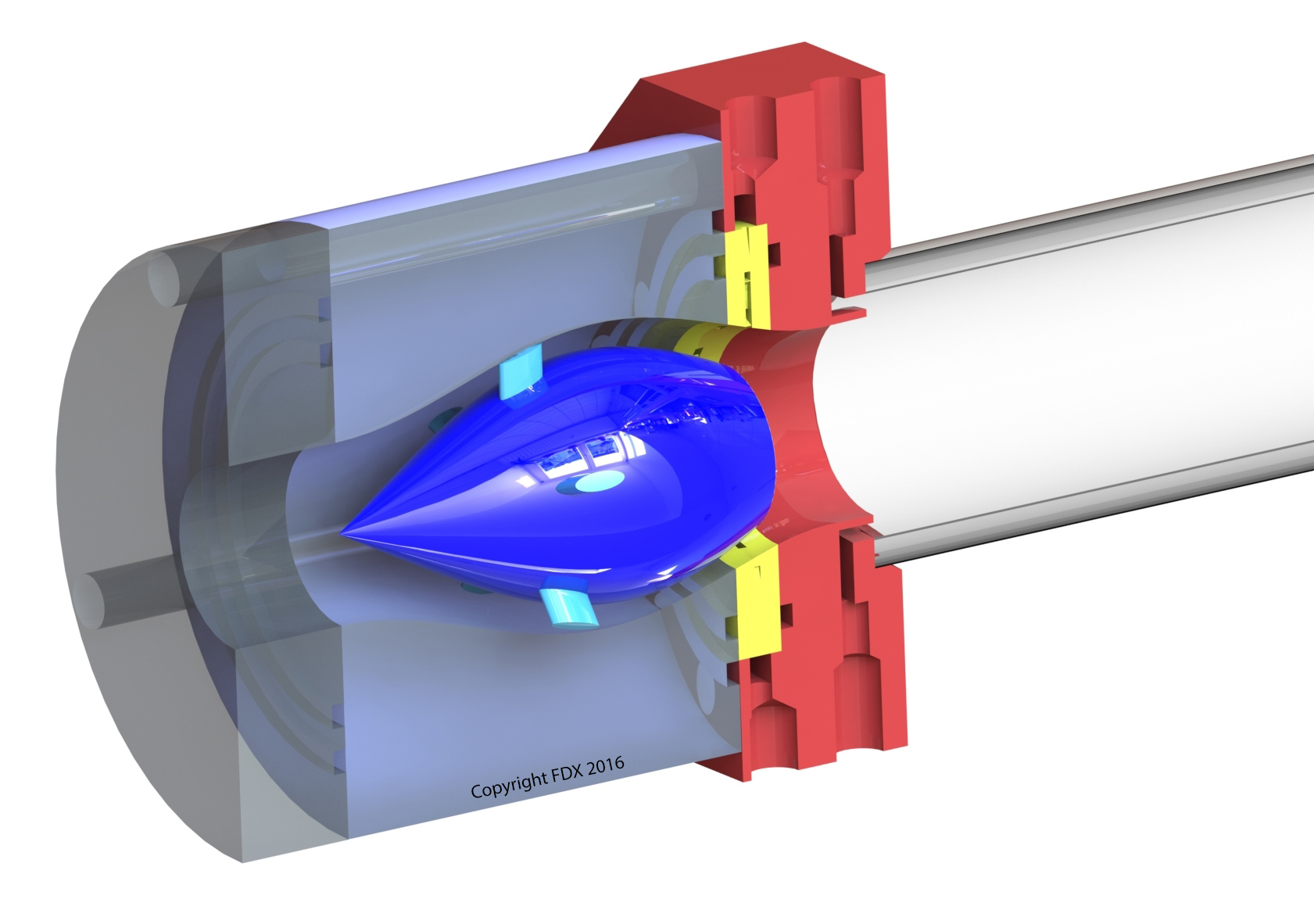

A fluidic diode is a passive device that has a lower flow resistance in the preferred direction than in the opposite direction. Simply put, it means that a fluidic diode has very low resistance in one direction and, depending on the design, very high resistance in the opposite direction. This can be used, for example, to prevent a flow from striking back. The principle generally works independently of the medium, be it a liquid or a gas.

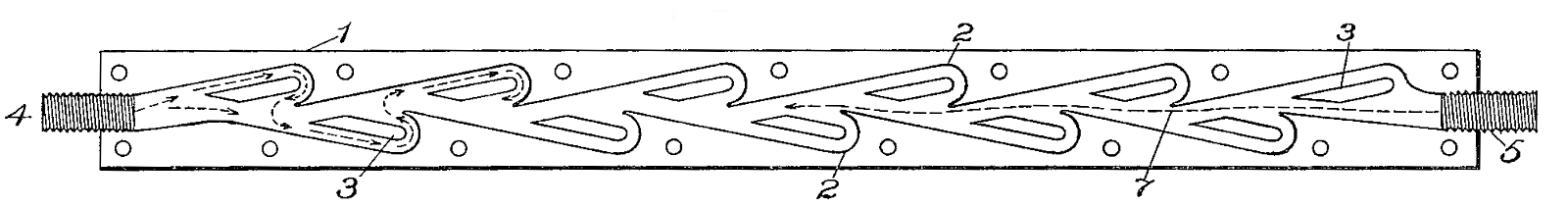

The basic idea was patented by Nikola Tesla in 1916 and is based on flow obstacles that create a rather laminar flow in the preferred direction and strong turbulence in the opposite direction. The great advantage of such a component is that these valves do not have any moving parts, react very quickly and are therefore virtually maintenance-free. The disadvantage of the components is that they do not completely stop the backflow, but only slow down the reverse flow significantly. Further details, which we are unfortunately not allowed to show here for legal reasons, can be found in the publications we have listed at the end of this page.