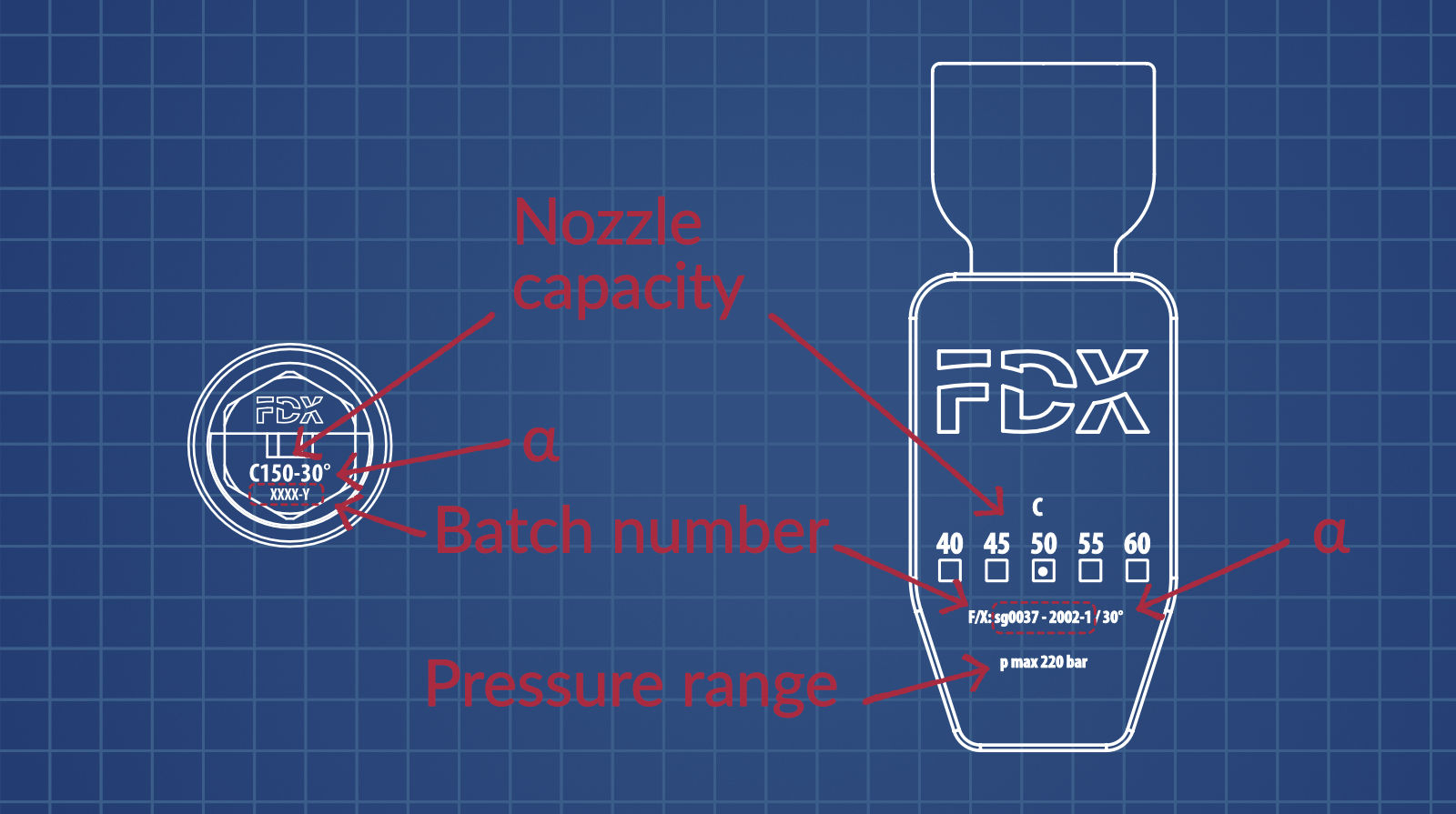

Nozzles are used in numerous applications. To select a nozzle with the right characteristic for an application is crucial for an optimal operation. This includes the effectivity and efficiency of the overall process. Therefore, we have compiled the necessary nozzle terms on this page, with an according explanations. If there remain questions, please do not hesitate to contact us.