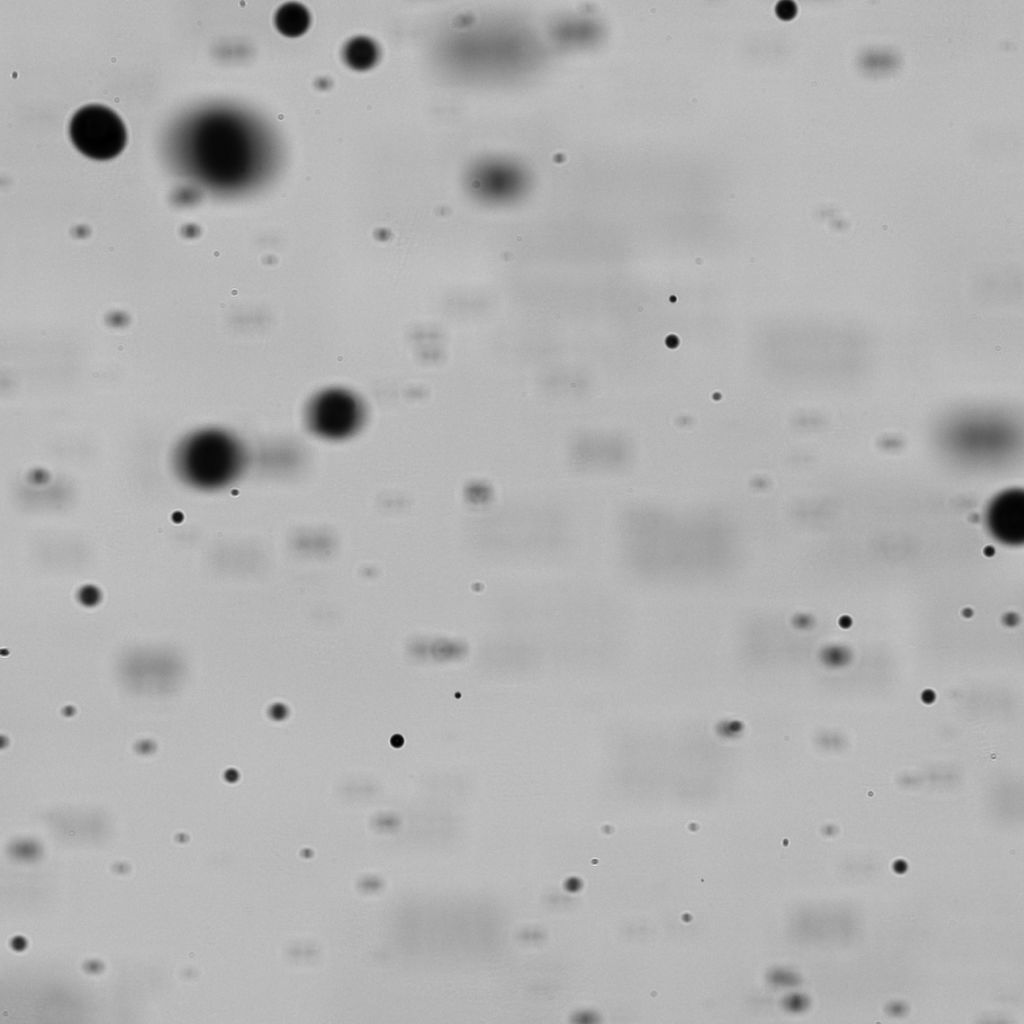

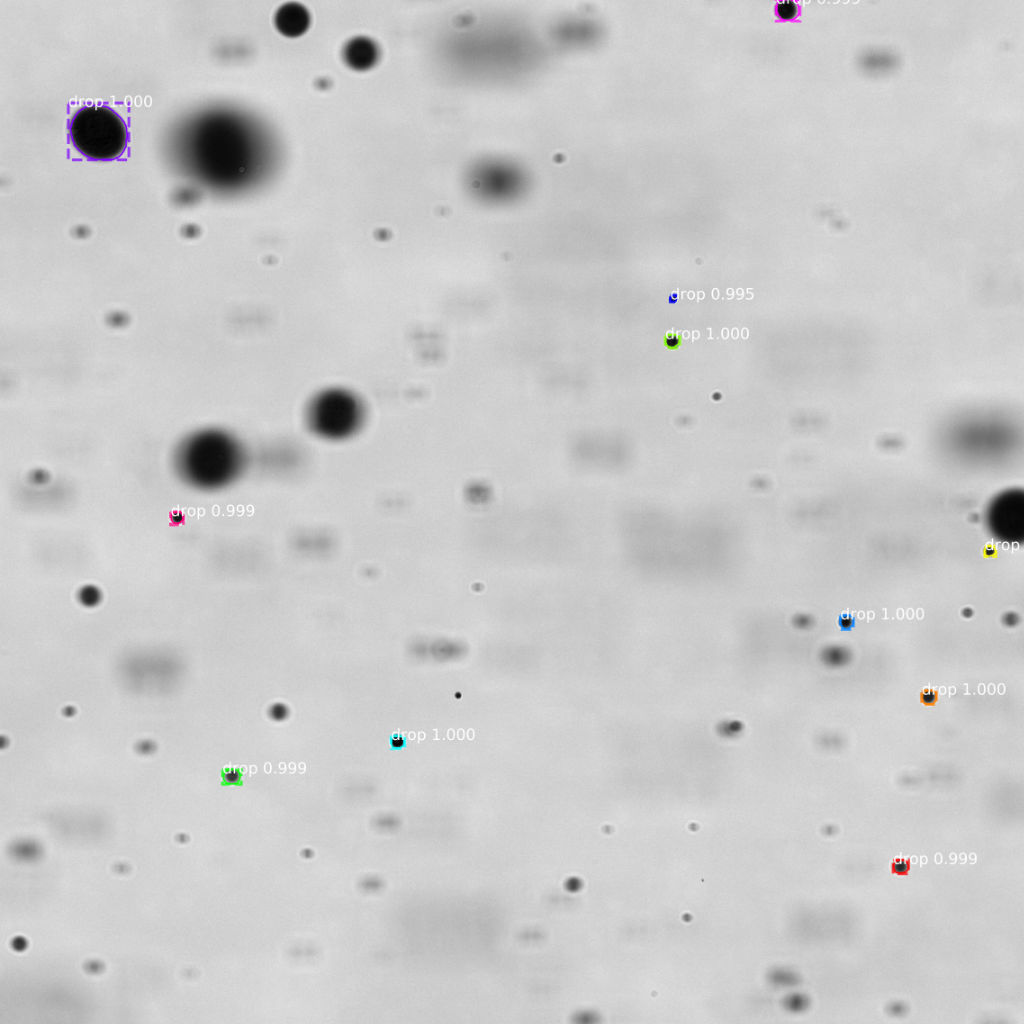

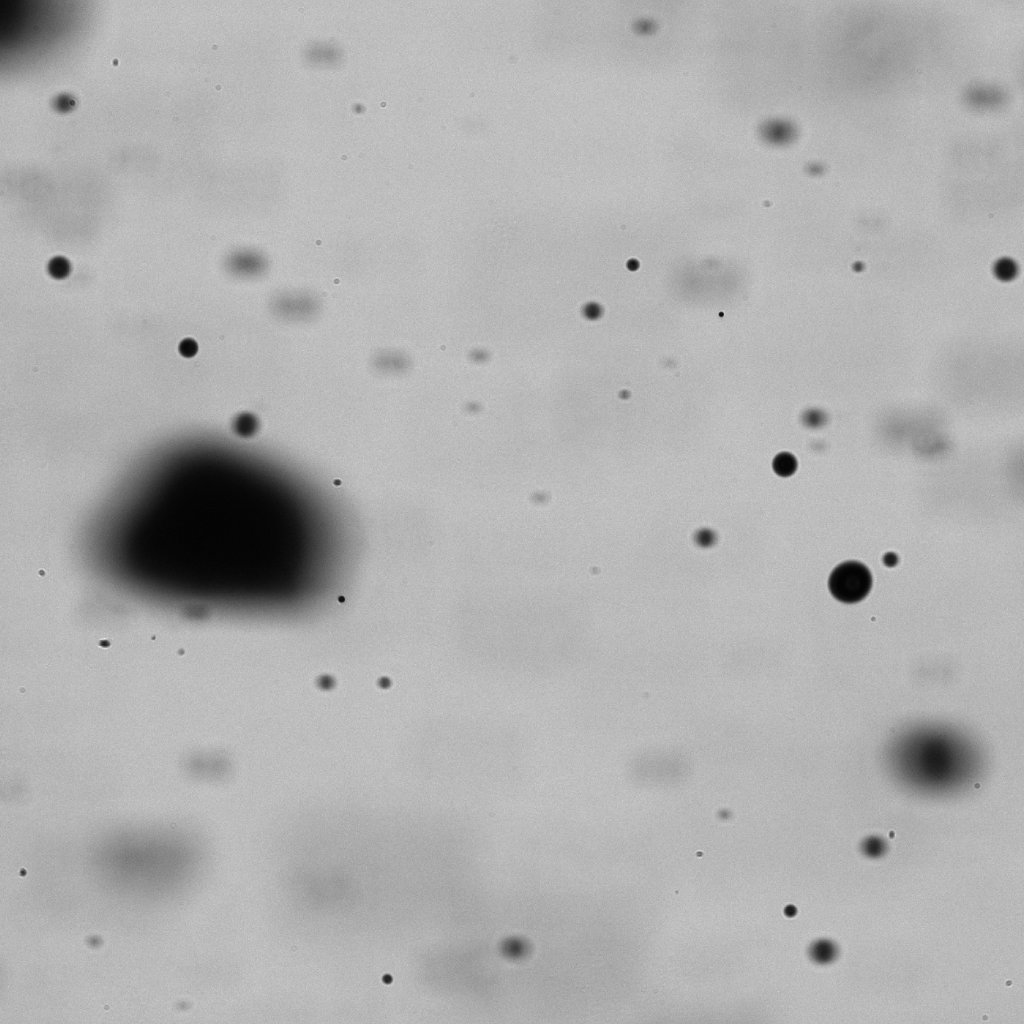

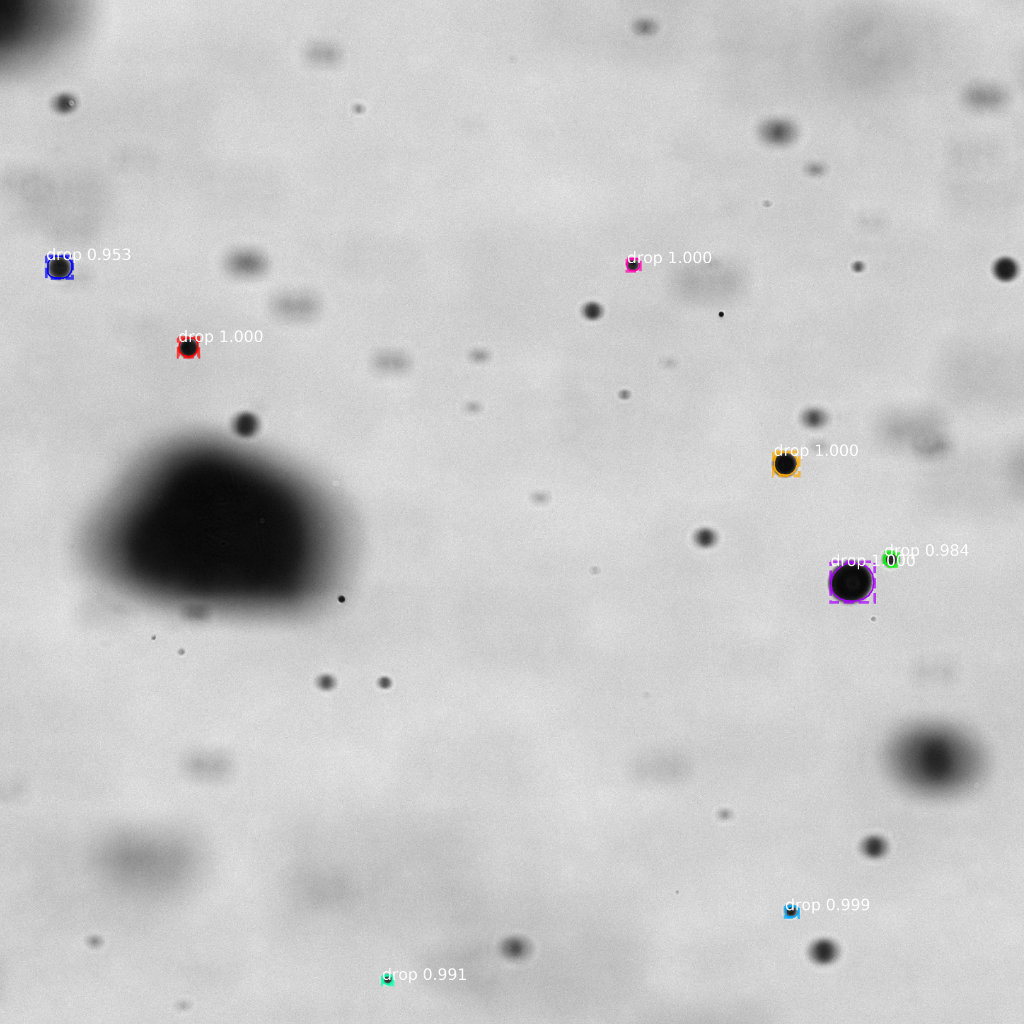

From high-pressure cleaners to asthma sprays, the distribution and application of liquids is an essential purpose of nozzles. In order to be able to use the right nozzle in a targeted manner, it is therefore essential to know its spray properties. The properties not only determine the efficiency of a process, but also its effectiveness. Droplets that are too small, for example, are simply carried away by convection during spray cooling, or merely wet the surface during a cleaning application without imposing mechanical forces. In contrast, droplets that are too large do not reach their point of application in an asthma spray.

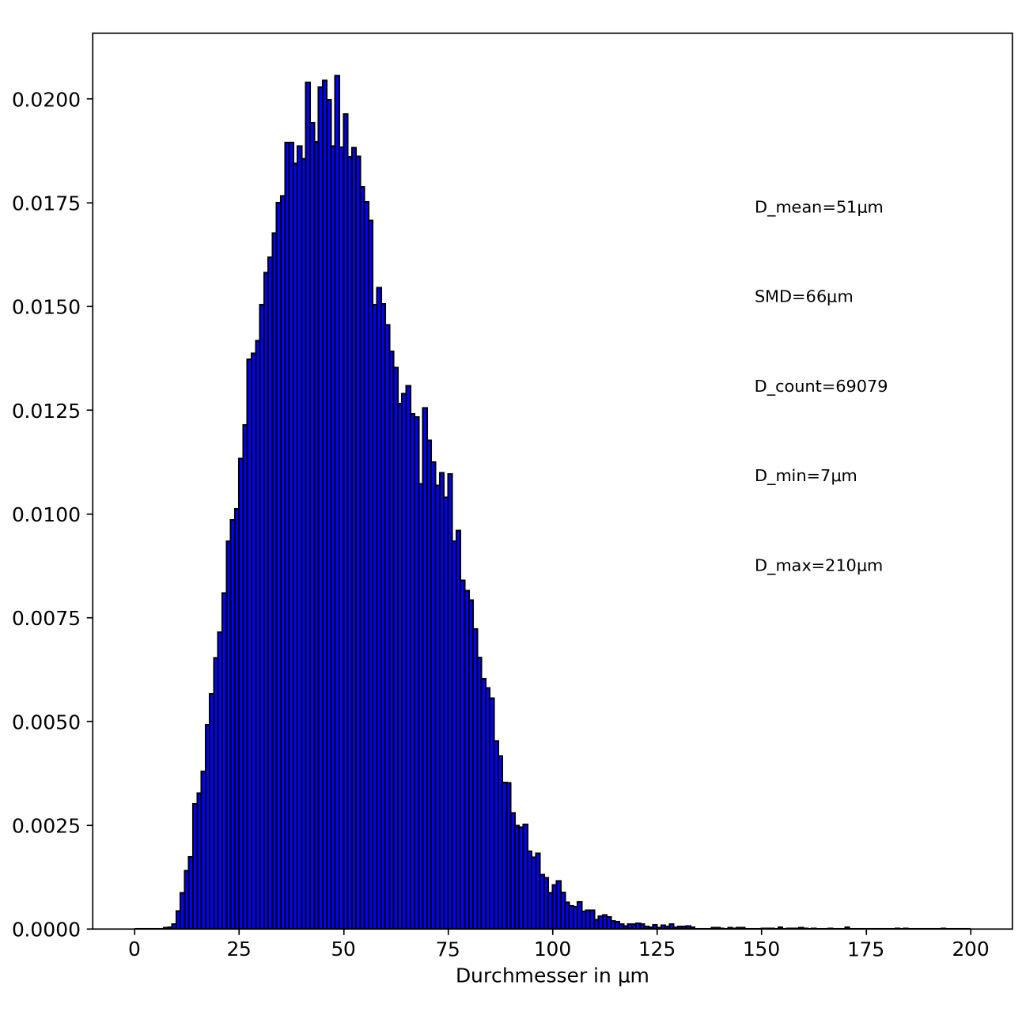

To make matters worse, the technically relevant nozzles do not deliver a constant droplet size over all droplets, but a size distribution that can also vary spatially and even temporally. The detection and especially the evaluation of these properties is often of great importance.