An emulsion is a mixture of two normally immiscible liquids. One of the two liquids is distributed in the other liquid in the form of fine droplets. Examples of emulsions are numerous cosmetic products, but also milk or mayonnaise.

The term nanoemulsion is used when the droplet sizes are in the range of a few hundred nanometers (20- 500 nm). Due to their small droplet size, nanoemulsions have advantageous properties such as a high surface-to-volume ratio, high stability and adaptable rheology. It is this property that makes nanoemulsions attractive candidates for a wide range of applications in various industries, including food, cosmetics, pharmaceuticals, drug delivery and material synthesis. For example, in the food industry, one of the most important applications of nanoemulsions is the embedding of lipophilic components such as flavors, vitamins and nutritional supplements. In addition, nanoemulsions can mask the unpleasant taste or odor of some bioactive substances in food, increase the stability of ingredients and improve their digestibility. Nanoemulsions are also used in the pharmaceutical industry, for example in the field of parenteral fat nutrition.

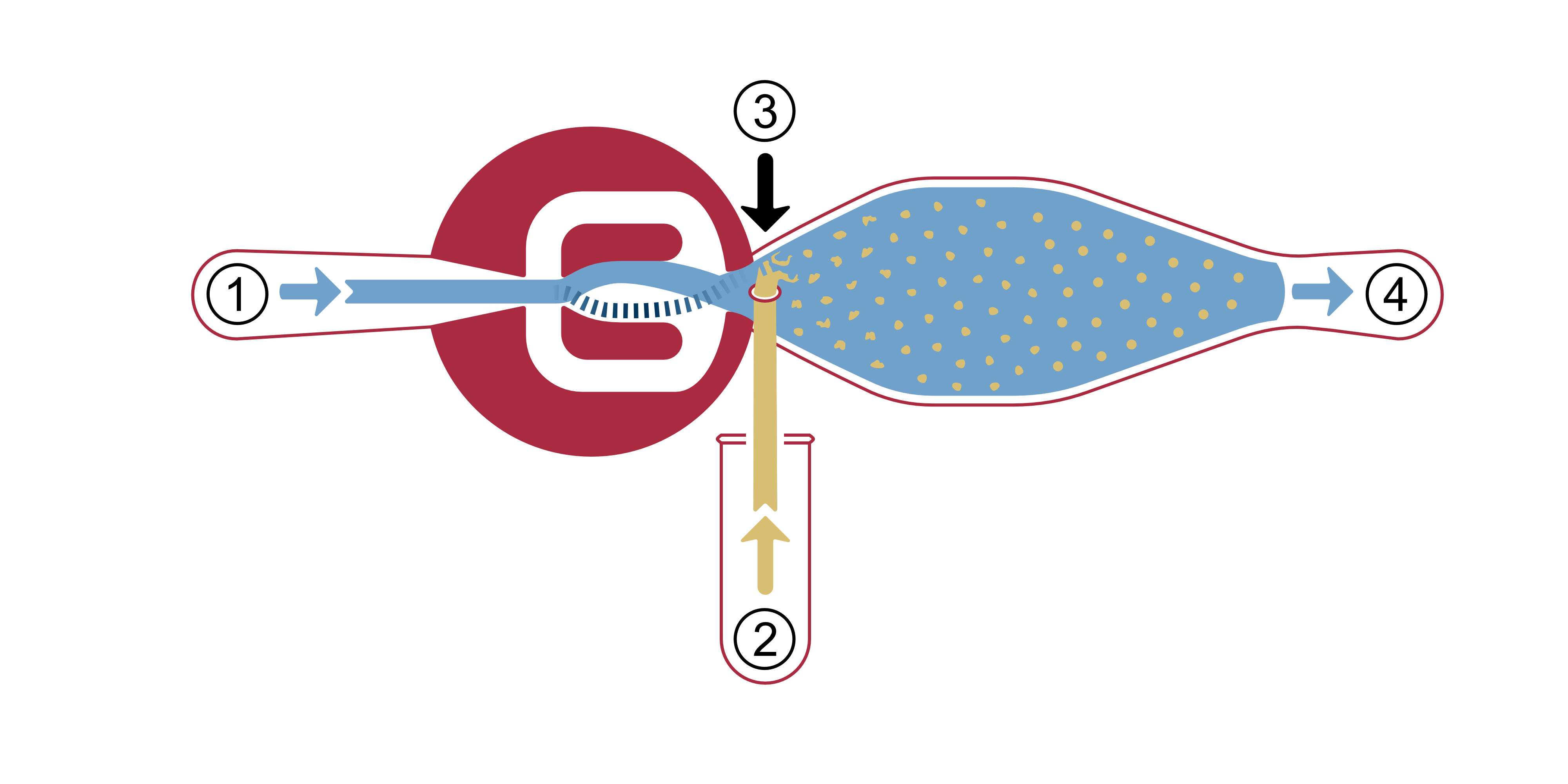

The formation of nanoemulsions usually takes place in a two-stage process: first a macroemulsion is produced, which is then converted into a nanoemulsion in a second step. Various techniques are available for this process, but high-energy methods such as high-pressure homogenization are frequently used in industry. One disadvantage of this method, apart from the high energy requirement, is that the homogenization process usually has to be repeated several times to achieve the desired properties. The production of nanoemulsions benefits from the use of our newly developed FDmiX platform, which enables the production of nanoemulsions in a single run without the intermediate step of a macroemulsion. In this way, a continuous flow-through process can be achieved.

The heart of the FDmiX mixer consists of an OsciJet nozzle that produces a moving jet without any moving parts. Depending on the flow rate and pressure, the water jet oscillates at a frequency of up to 5 kHz. This means that the jet moves from side to side up to 5000 times per second. The oscillating jet then leaves the nozzle and hits the secondary inlet of the oil phase in the mixing chamber and “cuts” the secondary jet into many small droplets, which are further reduced in size by the high shear forces in the mixer and thus form the nanoemulsion.