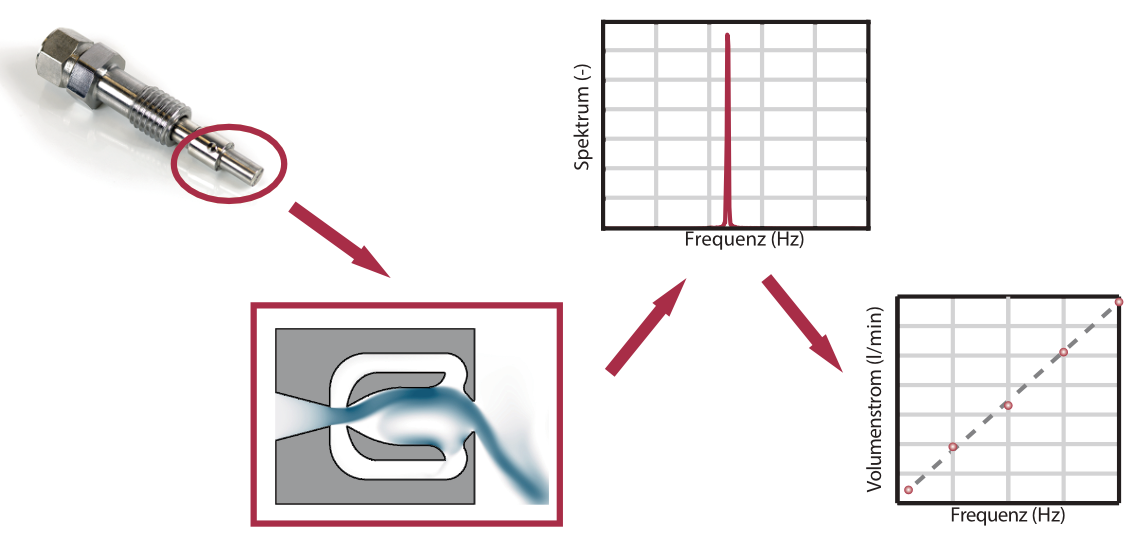

The OsciNet system takes advantage of the unique properties of the OsciJet nozzle. This is because the OsciJet nozzle generates a dynamic, i.e. oscillating, gas or liquid jet whose frequency is directly related to the current flow rate. The OsciNet system uses sensors (pressure sensors, microphones, accelerometers) to determine the frequency and can use this to determine the current flow rate. Depending on the sensors used, not only the flow rate (volume flow) but also blockages and malfunctions can be detected in a simple manner. In principle, the OsciNet system can be used with any OsciJet nozzle and even independently of the medium. The OsciNet System thus elevates the OsciJet nozzle to the status of the next generation nozzle, i.e. to “Nozzle 4.0”.